3- Calculating Weight of Rebar

3- Calculating Weight of Rebar

Let’s look at our foundation detail again,

Picture

2.6 Foundation Wall Detail

When we are calculating each concrete element,

we will calculate reinforcing steel goes in that element from bottom to up in

order.

In Continuous footing, detail is showing 3

#(number) 5 rebar continues and #5 rebar short way at 12” on center.

Our concrete was

Continuous Footings

= 116’x2’x1’/27=8.59 cy,

Rebar goes in this concrete element is ;

3#5x116’-0” continuous long way

and 117#5@2’-0” short way

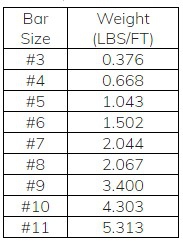

weight of #5 rebar from table 1.1 is 1.043 lbs per lf.

Table 1.1 Rebar Sizes

and Weights

Continuous Bar 3#5x116’-0” = 3x1.043x116 =362.9 lbs

Short Way Bar 117#5@2’-0” = 117x1.043x2 = 244 lbs

Plus, dowel goes in this concrete element also. Picture 2.6

calls for the dowel as the same as wall vertical reinforcing which is also #5

at 12” on center.

To be able determine the length of the dowel we need to

learn couple more subjects.

Lap splices and Hooks.

3.1. Lap Splices and

End Hooks

Total length of our continuous footings is 116’-0”. Our foundation is 34’ long ways and 24’ short ways. We can buy stock length of rebar for 40’ and we can cut it for the lengths of 34’ and 24’. In this case we don’t need any lap splice for continuous bars. But usually transportation of 40’ rebar is not possible for small orders. If you are not getting 20 Tons full trailer load rebar, you have to pick up your rebar from local building suppliers. Most local suppliers carry 20’ long rebars. When you are installing rebar, you have to lap the bars to transfer stress from one bar to other. Lap bars needs to be wired together.

Picture 2.7 Lap

Splice for #5 rebar

You have to lap the bars to each other, as per engineers

referred lap splice table. Engineer usually provides a table for tension

splice, compression splice for each PSI of concrete design mixes or sometimes

calls generally min. required lap splice is 48 bar diameter. This is given by

the engineer as per their calculations. 48 bar diameter mean is 48 times

diameter of the rebar.

Keep this in your mind #8 bar is 1” diameter. To find out

diameter for the other rebar sizes just divide the size the 8. Such as,

#5 = 5/8” diameter,

#4=4/8” =1/2” diameter,

#3=3/8” diameter,

#9=9/8” =1 1/8” diameter.

When you calculating 48 bar Diameter lap splices,

For #3, 48 Bar Diameter Lap Splice = 48 x 3/8 (Diameter of

#3 rebar)=18” =1’-6”,

For #4, 48 Bar Diameter Lap Splice = 48 x 4/8(Diameter of #4

rebar)= =24” = 2’-0”

For #5, 48 Bar Diameter Lap Splice = 48 x 5/8(Diameter of #5

rebar)= =30” =2’-6” (used in Picture 2.7)

For estimating purpose, we will use 48 Bar Diameter lap splice for all our lap splices to be able to calculate simpler and faster. Also we are eliminating all concrete coverage requirements for rebar. In footings rebar coverage against earth is as per ACI 3” .

Picture 2.8 Rebar

Coverage in Footing

In picture 2.8, footing width is 2’-0” and if we deduct 3”

for coverage from each side , short way rebar length will be 1’-6” . But for

the estimating purpose we will not deduct for any concrete coverage

requirements. We will calculate as 2’-0” short way bar.

For the purpose of the estimating, I will not get in to

details of lap splicing for compression or tension bar. I will be using 48 bar

diameter lap splice for all rebar splicing and for all the development lengths

besides hooks.

We will be using table 2.5 and Table 2.6 for our rebar laps and hooks.

|

Bar Size |

Bar Dia. (in) |

48” Dia. Lap Splice (in) |

|

#3 |

3/8 |

18 |

|

#4 |

1/2 |

24 |

|

#5 |

5/8 |

30 |

|

#6 |

3/4 |

36 |

|

#7 |

7/8 |

42 |

|

#8 |

1 |

48 |

|

#9 |

1 1/8 |

54 |

|

#10 |

1 1/4 |

60 |

|

#11 |

1 3/8 |

66 |

Table 2.5 48” Diameter Lap Splices

|

END HOOKS |

180° |

90° |

|

Bar Size |

Length (in) |

Length (in) |

|

#3 |

5 |

6 |

|

#4 |

6 |

8 |

|

#5 |

7 |

10 |

|

#6 |

8 |

12 |

|

#7 |

10 |

14 |

|

#8 |

11 |

16 |

|

#9 |

15 |

19 |

|

#10 |

17 |

22 |

|

#11 |

19 |

24 |

Table 2.6 End Hooks

Let’s go back to our continuous footing , we had

Continuous Footings =

116’x2’x1’/27=8.59 cy

And

Continuous Bar 3#5x116’-0” = 3x1.043x116 =362.9 lbs

Short Way Bar 117#5@2’-0” = 117x1.043x2 = 244 lbs

Now we can calculate the weight of the wall dowels,

Picture 2.9 Dowel

Length = Lap Splice + Footing Thickness + 90° Hook

Size of the dowel to match vertical rebar which is #5 from

Picture 2.6 Foundation wall Detail,

Lap splice for #5 is 30” from Table 2.5 48” Diameter Lap

Splices,

90° Hook for #5 is 10” from Table 2.6 End hooks,

Footing Thickness was 12” from picture 2.6 and we don’t

count for rebar coverage for estimating purpose, so we get full thickness .

Dowel Length = (Lap Splice) 30” + (90° Hook )10” + (Footing

Thickness) 12” = 52” = 4’-4”

Dowels 117#5x4’-4”=117x1.043x4.33

=528.39 Lbs = always round up = 529 lbs

(1.043 weight of #5 rebar from table 1.1 and 4.33=4’+4”/12)

Now , we can figure total weight of the rebar needed to

build continuous footings.

Continuous Footings = 116’x2’x1’/27=8.59 cy

Continuous Bar 3#5x116’-0” = 3x1.043x116 =363 lbs

Short Way Bar 117#5@2’-0”

= 117x1.043x2 = 244 lbs

Dowels 117#5x4’-4”=117x1.043x4.33 =529 Lbs

Total =1,136 Lbs

Comments